Drive Productivity and Safety with QS Solutions

About Us

Building QS Solutions for Every Challenge

The business landscape has undergone a dramatic transformation over the last 20 years. Advances in technology have reshaped how we connect with customers, operate, manage supply chains, and even the products and services we offer. Despite these changes, many business strategies have remained static, leaving high-performing companies struggling to adapt and reach their full potential.

At QS Solution, we believe that every business can thrive—delivering exceptional performance, improved productivity, enhanced safety, and better outcomes for both employees and customers. But to achieve this, the right solutions are essential.

Solutions

End-to-End Solutions for Efficiency Safety,

and Growth

Lean manufacturing

5S System and 5S Training on site.

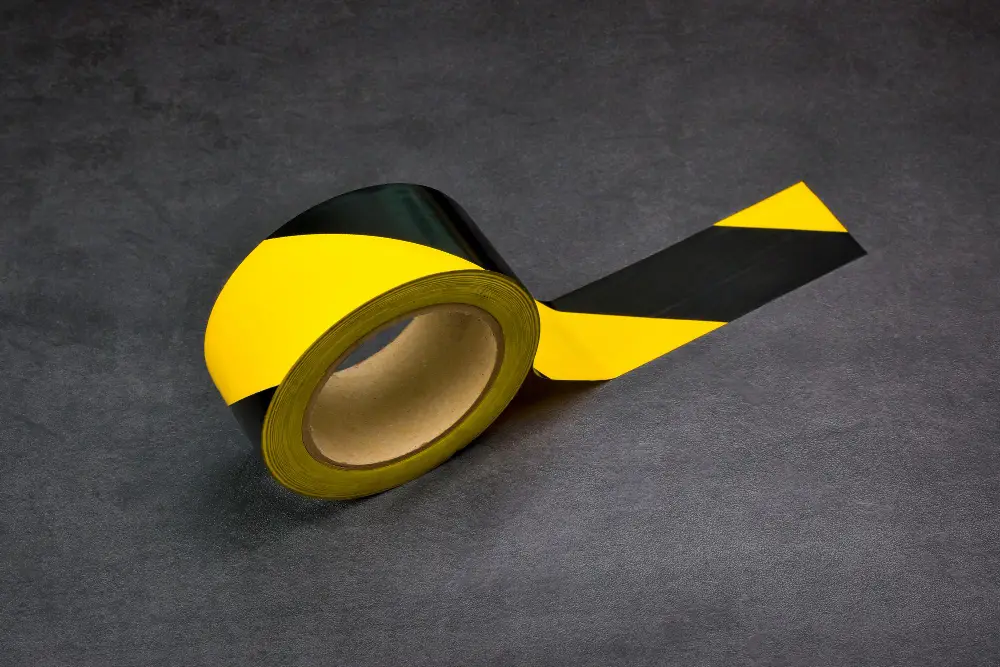

Visual Management

Implementing floor markings

Quality, Health, Safety and Environment

Our Team

Empowering Businesses with the Right Solutions

At QS Solution, we believe that every business can thrive—delivering exceptional performance, improved productivity, enhanced safety, and better outcomes for both employees and customers. But to achieve this, the right solutions are essential.

Products

Our Product Solutions for Safety,

Efficiency, and Compliance

Ready to Unlock Your Business Potential?

Let QS Solutions help you take control of your business environment. Talk to our team today and start implementing strategies for success. Whatever your business challenge, we have the solution.

FAQ

Frequently Asked Questions (FAQs)

What is Continuous Improvement?

Continuous improvement is an ongoing process of evaluating and refining business operations. It involves identifying areas for improvement, whether in efficiency, reducing waste, or enhancing customer experiences, and making incremental changes. Over time, these small adjustments lead to increased productivity, cost savings, and better outcomes for both the business and its customers.

What is Lean Management?

Why Choose the 5S System?

How Can 5S Improve Employee Engagement?

What Benefits Can I Expect from Visual Management?

How Do I Get Started with Lean Management?

Social Links